Are you wondering what the secret behind a laser cleaning machine is? You’ve come to the right place. Here, we’ll reveal the 4 mysteries of how laser cleaning machines work so that you can get on with perfecting your project and make it shine!

What are the Benefits of Laser Cleaning?

Using laser cleaning technology offers many advantages to traditional cleaning methods. Some of these benefits include:

- It is non-contact, meaning it requires no physical contact with the material being cleaned, providing a significant benefit when cleaning fragile or delicate surfaces.

- Laser cleaning machines work without the use of hazardous chemicals, reducing health and environmental risks associated with traditional cleaning methods.

- Pre-cleaning prepping is greatly reduced due to the extreme accuracy of laser cleaners; they can access complex shapes, 3D contours, recessed areas and other hard-to-reach spots with ease and precision.

- Large areas can be cleaned quickly as laser machines can be programmed to run large scan patterns in single operations on flat surfaces.

- The process is also repeatable and consistent – lasers can clean multiple identical objects to precise parameters in a fraction of the time compared to manual techniques that take much longer for more sporadic results.

- It produces no secondary waste or abrasion residue and leaves behind a clean surface free from oxide layers, oils and lapping compounds so there’s no additional finishing required after laser treatment is complete.

How Does Laser Cleaning Work?

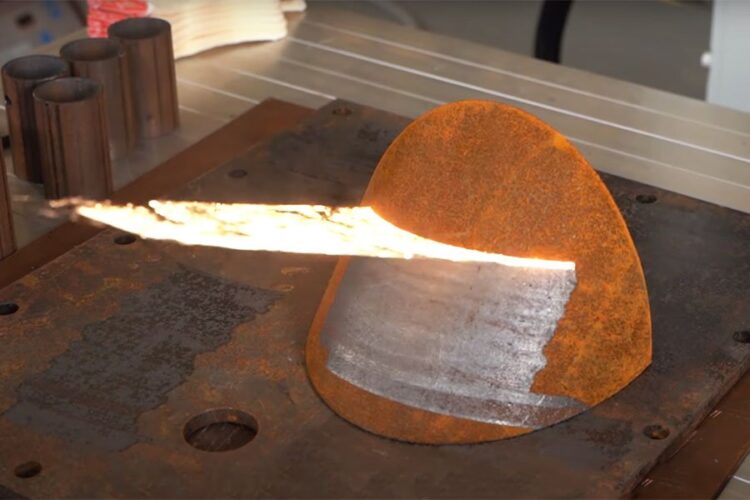

It uses pulses of light from a laser source to remove contaminants from a wide range of surfaces. It’s essentially an eco-friendly method for removing dirt, deposits, coatings and rust from metal objects and other surfaces with minimal effort and mess.

How does it work? Here are the basics that you should know about the process:

- Laser Energy: Pulses of highly concentrated energy efficiently remove dirt and grime without damage to the cleaned surface. The size, intensity and duration of the laser beams can be programmed depending on the type of material that is being cleaned.

- Laser Wavelength: Different types of lasers have different wavelengths, so it’s important to use the right type for the job at hand. For example, red lasers will be more effective on rust while blue lasers work better with nonmetallic materials such as microscopes or jewelry pieces.

- Heat: The high energy dispersion heats up targeted areas at rapid speed in order to remove contaminants quickly and easily without causing damage or leaving residue behind afterwards; it evaporates just like water does when exposed to heat or pressure!

- Control: It comes with precise control over how much power is used for each pulse, allowing for accurate determination of how much heat needs to penetrate any particular material that needs cleaning – this makes sure all those hidden layers are removed safely!

- Maintenance: Due to its advanced components and built-in capability for intelligent operation, a laser cleaning machine requires only minimal maintenance compared to traditional methods like sandblasting which need regular setup time due special equipment requirements like abrasive tanks filled with liquid media or dry media – meaning they take up more space in your factory too!

What Materials Can be Cleaned with Laser Cleaning?

These machines can be used to clean a variety of materials. Different types and sizes of lasers can be used for it, depending on the type of material that needs to be cleaned. Generally, metals and alloys, as well as paints and coatings (such as chrome or ceramic coating) are routinely cleaned with laser technology. Non-metallic materials such as plastic and rubber can also be successfully cleaned with laser machines.

It has proven effective on alloys such as stainless steel or aluminum, where it removes oxides or other contaminants from the surface without damaging the base material. It is also used for maintenance purposes on infrastructure components such as bridges and railways that need to be free of mud, rust or other soil deposits in order to increase their lifespan and durability. Lasers are also used in artwork restoration projects because they protect sensitive surfaces while gently but efficiently removing dirt and debris that may have accumulated over time.

What Safety Measures Should Be Taken When Using Laser Cleaning Machines?

They are powerful tools capable of removing unwanted particles, dirt, old paint and other coatings from a variety of hard surfaces. This efficient process is becoming more common in various industrial sectors, such as metal processing, automotive detailing and construction.

While it is a great way to quickly and effectively remove unwanted particles from surfaces, it’s important to take safety measures when using these devices. Here are some essential safety tips to keep in mind when you’re working with a laser cleaner:

- Wear Appropriate Safety Equipment: Be sure to wear eye protection when you’re operating the machine and stay away from any bare skin or clothing that can be damaged by the laser beam.

- Minimize Exposure Time: Limit the amount of time your body is exposed to the laser beam while you’re using the machine, and make sure that you stay at least ten feet away from surfaces being cleaned.

- Follow Manufacturer’s Instructions: Everyone has specific instructions for how long it should be used on certain materials and how close it should be held to those materials – be sure to follow these instructions carefully for maximum safety and efficiency.

- Be Mindful of Environment: It’s important to keep in mind that environmental conditions can affect the efficacy of these machines; for example, moisture-heavy air can diminish its power and potentially cause hazardous reflections when used outdoors or near bodies of water.

- Have Someone Monitor Cleaning Process: Having someone else present during your operation will help ensure that all safety guidelines are being met while aiding in troubleshooting if any issues arise throughout the cleaning process.

Conclusion

In conclusion, understanding the science behind laser cleaning machines is important for folks considering this process. This technology has a wide range of applications, from removing coatings to maintaining surfaces in harsh environments. The diversity of features and accessories available make this versatile tool a fast and cost-effective solution for almost any cleaning need.

It’s important to remember that while this kind of cleaning is popular, safety is key. Proper personal protective equipment should always be worn when operating the machine, and approved goggles should be worn at all times. Proper technical training must also be followed in order to ensure that you are using the equipment correctly and efficiently.

With efficient operations and proper safety measures, laser cleaning machines can become an essential tool in any industrial environment!